Thomas McQuillan is a business analyst for Baldor Specialty Foods, and he has led the company’s efforts to become more sustainable while also cutting costs. McQuillan has introduced several initiatives to utilize the 10,000 pounds of food scraps created by the company every day. Prior to McQuillan joining Baldor, food waste was picked up by its waste hauler, but today, they use these scraps to generate income, unlock valuable nutrients, compost, and feed the hungry. Food Tank had the opportunity to speak with McQuillan about the company’s efforts to divert food scraps from landfill and ensure that the hard work of farmers, producers, and processors does not go to waste.

Food Tank (FT): How did you get involved in managing Baldor’s sustainability initiatives?

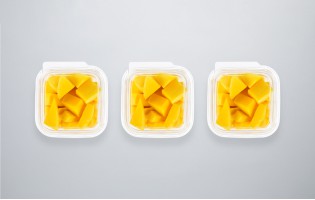

Thomas McQuillan (TM): Baldor Specialty Foods’ core business is 80 percent produce distribution and 20 percent specialty food distribution. A specialty food is anything that is not a fruit or vegetable, including olive oils, frozen hors d’oeuvres, truffles, etc. Within our company, we have a subsidiary called Baldor Fresh Cuts. Baldor Fresh Cuts processes some 60 different fruits and vegetables into different shapes and sizes each day. There are more than 500 SKUs that are available to our customers on a daily basis, and about 1,400 SKUs in total, which include items that can be special-ordered. As a result of that food production, if, for example, we’re cutting a carrot up into carrot sticks, there are carrot tips and peel leftover. I was asked to look at all that excess food product we generate in Fresh Cuts and do something with it, other than send it to landfill. That’s how our sustainability work at Baldor started. I wasn't brought into Baldor to look solely at sustainability. Specifically, I was brought in to assist the President with special projects, and this is just one of them that has taken on a life of its own.

FT: Can you describe Baldor’s Fresh Cuts program?

TM: Fresh Cuts sets us apart from other food distributors in a couple of ways. We don’t just deliver food. We source the highest quality produce and process this food into specific cuts depending on the needs of the chef. Utilizing Baldor’s Fresh Cuts service allows the restaurant owner, chef, kitchen manager, and staff more time to focus on other aspects of their business. Our full line of Fresh Cuts allows our customers to yield 100 percent usable products while reducing waste, eliminating prep time, and improving profitability. Baldor can supply customers with all their Fresh Cuts needs. We offer everyday kitchen staples such as carrot coins and zucchini matchsticks, as well as special cuts such as Chateau squash and Tourneau potatoes for more lavish presentations. Items arrive uniformly cut and crisp—fresh every morning—allowing chefs to do what they do best: cook.

FT: Can you give us a glimpse into the Baldor food cycle?

TM: As a distributor, we are very closely aligned with our growers and shippers. We work in conjunction with them to create an annual cycle of food production, collection, and transportation, and then we distribute this produce throughout our market. Our customers demand certain products year round, such as strawberries. We have to make sure we can source the strawberries from somewhere around the world, all year round. The food cycle looks something like this—food production moves from the northern hemisphere to the southern hemisphere and then back north again. As the year progresses, the food is extracted from farms and delivered to us based on what is available in those various regions. What keeps us relevant as a distributor is the complexity around growing and distributing food: temperature, storms, and logistical disturbances. This uncertainty is what creates the volatility in market pricing and product availability. For example, it may be that avocado trees from Mexico received too much rain, and so they have not been able to harvest. As a result, we have to find another source. We are constantly forced and challenged to remain nimble and resourceful. Additionally, we have to make sure that we always have access to produce to meet the needs of our customers. We no longer have very specific seasons for many fruits and vegetables due to the fact that we source both locally and globally. With that said, we are also very involved in supporting local agriculture with our Local Pledge initiative. By taking the pledge, customers authorize Baldor’s sales team to substitute commodity items with comparably priced local alternatives whenever they are available. Consumers can actually log onto our site and see which restaurants and chefs are ordering local food to help us build a stronger regional food system.

FT: What types of food scraps does Baldor generate and how does the SparCs program address unused food?

TM: When we think about all the produce we process into carrot sticks and diced onion, for example, we should think about a use for all of that product. The carrot peel and tip should have a purpose no differently than the carrot stick we are producing. It is important to think about a use for the whole vegetable or fruit. If we are going to be forced to peel a carrot and take the top and bottom off, what can we do with those parts of the carrot so that they are never considered garbage or waste? We need to identify opportunities for the whole product, not just parts of it. SparCs (scraps backward) is an answer to this challenge.

The SparCs program looks at all the produce we use in processing and aims to utilize 100 percent of that product. Specifically, we are talking about food trim resulting from food production. The second piece is product that either ripens in our facility or does not meet our criteria for sale for some reason. In the event that we cannot sell the product, we look for an end user for the product. We try to donate as much as possible as the need for fresh produce among the food insecure is as crucial as ever. We utilize waste to water systems and send the product to a composter. Our last resort is to treat the food as waste.

FT: Do quality standards and the expectations of consumers interfere with using all food scraps?

TM: We want to make sure that we are always providing the highest quality, safest food as possible. In our operation, there are critical control points along the production cycle to ensure safety. After we peel a carrot, for example, the peelings enter what we call the “de-box” room, and then the cleaned carrot goes into production. During that production process, it is run through one of our critical control points: a bath of water that has a portion of chlorine in it to kill any pathogen that might still remain on that vegetable. Another critical control point occurs at the end of the process. The product must go through an x-ray machine to make sure there are no physical contaminants. The SparCs that are collected within the “de-box” room would not have gone through these critical control points, so we are always concerned that those products are further processed before they are consumed by humans to ensure that any pathogens are destroyed. For example, we’ll work with a soup company as they further process that food by cooking it, but we wouldn’t be interested in somebody just taking the SparCs and making a salad.

FT: How does Baldor feel about composting food scraps?

TM: Composting is a great solution for a lot of food products, but I think it becomes the best solution for food products that are inedible. Think about the top of a bell pepper, for example. That little stem would be too fibrous to eat. Those kinds of products should always be composted and never sent to landfill.

Composting becomes challenging when the processing facility is in an urban area, and the composting farm is a considerable distance away. If we consider food products that have no value for human consumption and we plan to compost them, the life cycle of composting takes approximately nine months. During the first 90 days, the food is going to release a considerable amount of odor in the rotting process. There aren't too many places in urban environments where the community will welcome that kind of odor on a regular basis, particularly in the summer months. Transportation also becomes an issue. Produce is 90 percent water. When you are hauling food waste, you are hauling water. If the composting facility is 60 miles away, there is a considerable carbon dioxide release in the process of driving the food to the composting facility. You must also consider wear and tear on the truck, fuel, and the cost of the driver. This is why composting becomes a challenge. However, it’s still a better solution than sending food to landfill.

Additionally, composting must be handled properly. Professional composters understand that the food needs to be treated in a particular way and that the material has access to oxygen. In the absence of oxygen, the product will anaerobically digest, releasing harmful methane gas into the atmosphere. The methane release that occurs naturally makes the argument to consider anaerobic digestion of the product to capture that gas and create useful energy while at the same time creating a valuable compost in the process.

FT: Do you think there is a business opportunity behind wasted food?

TM: We do! There is a need for a cultural shift in the U.S. We need to once again value the delicious and nutritional food that we currently let go to waste. If we are talking about raw vegetables and fruits, we are probably referring to skins or peels. Food scientists tell us that this is where many of the nutrients reside. A tree or plant, in order to propagate, produces a skin or a layer to ultimately protect the seeds and to give them the nutrients they will need. In that process, the plant drives its nutrients to the outer layer. When we throw away the apple peel, we are losing valuable nutrients. As we eat these SparCs, we are deriving nutrition, and of course, we produce less waste. Whenever I think about sustainability, I think about expense reduction and the value that being more sustainable offers to the bottom line. Regardless of personal or commercial use, there are very few examples of how making our life more sustainable doesn't actually create economic value for us.

FT: Do you imagine food waste being a valuable commodity in the future?

TM: It will be, and I hope it’s not in years to come; I hope it’s now. There’s a lot of interest at the federal level as well as the state and local levels. For example, the Mayor’s zero waste challenge in New York City is a commitment to reduce waste and build awareness of the epidemic. I think the momentum is in our favor. For us to be successful and to reach the goal of reducing waste by 50 percent by 2030, there has to be a cultural shift and a change in attitude toward this food product, and I think that’s what you see happening. So, to answer your question, an emphatic “yes.”

FT: How have your goals for Baldor changed over the last few years?

TM: When we originally started looking into food waste reduction strategies, we thought that the slam dunk was going to be composting for all of our SparCs products. As we became aware of the difficulties involved in composting in an urban environment, we began to think about anaerobic digestion as a possible solution. I am a supporter of using anaerobic technology as part of the waste reduction solution. After food is anaerobically digested, the end product can be used as compost, essentially creating energy along with a valuable compost.

A year ago, I visited an anaerobic digestion chamber in California, and it occurred to me, “Wait a minute, that looks like good food. Why aren't we eating that food?” This forced us to prioritize, in every possible instance, the use of our SparCs for human consumption, animal consumption, anaerobic digestion, and then compost. I think the combination of these four respective components of our strategic plan will get Baldor to zero organic material sent to landfill very soon.

FT: How much food waste does Baldor sell per year?

TM: We refer to the product as SparCs, not scraps or waste! It’s increasing every day. We spoke about the animal feed solution. SparCs works really well as feedstock for animals. We collect a mix of a variety of vegetables and fruits in large, 1,000-pound recycled totes and ship those totes to local farms. The farmer can then utilize those totes and distribute them to their animals. This allows us to move a large amount of product in each delivery, and we can collect the product easily in our production facility. We are partnering with more and more farmers to create feedstock for their animals. When you think about the digestive system of pigs, they are not too different from our own. Specifically, pigs and humans have a difficult time digesting raw grains, but they do a good job at digesting raw vegetables. With SparCs, we have an opportunity to provide feedstock composed of delicious and nutritious foods for these animals, and give them the protein and vitamins they need. In the end, the food also avoids landfill! I should mention, this is not always an easy sell—you have to convince the farmer to change their processes—but every day, we’re making strides, and we are bringing on additional partners.

FT: Baldor partnered last year with Misfit Juicery. Do you see similar partnerships in the future?

TM: The juicing opportunity works well, because it is a great way to process a lot of SparCs. When we juice, we are creating a food product for human consumption. It is required that the juicer treats the juice with high-pressure processing (HPP), or pasteurizes it, to ensure that the juice is safe for consumption. We look to grow with Misfit, and there may be opportunities with other juicers as well.

One opportunity to consider is working more closely with a donation partner to create a consistent stream of SparCs that can be used in the creation of soups and broths to feed the food insecure. Instead of them sourcing whole carrots, onions, and celery to make a mirepoix, maybe we could provide the SparCs on a regular basis. In this instance, we would be taking steps to solve two issues: feed the hungry and answer the sustainability challenge at Baldor to reduce food otherwise destined to landfill.

FT: How do you deal with waste at home?

TM: I love this question! Food waste reduction starts at home. What happens in my house is that any product leftover from cutting a vegetable goes into a freezer bag and is put into the freezer. All vegetable SparCs are included without exception. It could be an onion top, or it could be the outer leaves of the romaine lettuce. On Fridays, my family and I take out the freezer bag and create a vegetable broth. The broth is then used to make a risotto or vegetable soup that Friday night. Everybody can do this at home. There are a couple of benefits. One, you are gleaning all that nutritional value out of these vegetables that you might have otherwise discarded. Two, you have accelerated the composting of that product. In the end, this product will compost and become dirt much faster than raw vegetables otherwise would.

To read a Food Tank interview with Baldor president Michael Muzyk about WastEd, click here.

Fruits

Fruits  Organics

Organics  Vegetables

Vegetables  Fresh Cuts

Fresh Cuts  Meat & Poultry

Meat & Poultry  Grocery

Grocery  Dairy

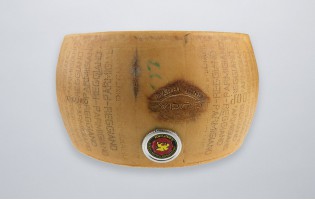

Dairy  Cheese

Cheese  Bakery

Bakery  Seafood

Seafood